Pure PEEK 3D Printing Filament for Industrial, Aerospace & Medical Prototyping in Westmead NSW 2145, Australia

PEEK-1000 (ARKPEEK™-1000) is a premium, unfilled, 100% pure Polyetheretherketone (PEEK) filament developed for the most demanding engineering, aerospace, medical, and industrial applications. As the toughest and most ductile grade in the PEEK family, PEEK-1000 delivers an exceptional balance of mechanical strength, impact resistance, thermal stability, chemical resistance, and biocompatibility. see silver3d

Available and supported in Westmead, New South Wales 2145, Australia, PEEK-1000 is the preferred choice for engineers, researchers, and manufacturers who require high-performance parts capable of operating in extreme environments while maintaining toughness and reliability

3D-PEEK-1000 Faliment.

Key Features & Benefits

-

100% pure, unfilled PEEK resin for maximum toughness and ductility

-

Exceptional impact resistance & elongation at break compared to reinforced PEEK grades

-

Outstanding thermal performance, suitable for continuous high-temperature service

-

Excellent chemical resistance to aggressive chemicals, oils, fuels, and solvents

-

High purity & biocompatibility, suitable for sterilisation processes

-

Inherent flame retardancy (UL94 V-0) without additives

-

Excellent wear & abrasion resistance

-

Ideal for functional prototypes, tooling, and end-use parts

-

Designed for industrial-grade 3D printing systems used in Westmead NSW and across Australia

Target Applications (Westmead NSW 2145 & Australia)

PEEK-1000 is widely used in industries that demand toughness, thermal stability, and chemical resistance:

-

Medical & Dental (Non-Implantable)

-

Sterilisable surgical guides

-

Medical device housings

-

Instrument prototypes

-

-

Aerospace

-

Lightweight brackets & ducts

-

Interior structural components

-

High-temperature functional prototypes

-

-

Chemical Processing

-

Seals, valves, pump components

-

Corrosion-resistant fixtures

-

-

Electrical & Semiconductor

-

High-purity insulation components

-

Wafer carriers & fixtures

-

-

Automotive & Industrial Engineering

-

Under-hood components

-

Jigs, fixtures & tooling

-

These applications align strongly with engineering, medical research, and industrial facilities in Westmead NSW 2145.

Material Properties Overview

Physical Properties

3D-PEEK-1000 Faliment

| Property | Test Standard | Typical Value |

|---|---|---|

| Density | ISO 1183 | 1.30 – 1.31 g/cm³ |

| Filament Diameter | — | 1.75 mm |

| Colour | — | Natural / Light Brown |

| Flame Rating | UL94 | V-0 |

Mechanical Properties

3D-PEEK-1000 Faliment

| Property | Test Standard | Typical Value |

|---|---|---|

| Tensile Strength | ISO 527-2 | 100 – 130 MPa |

| Tensile Modulus | ISO 527-2 | 2,400 – 4,400 MPa |

| Elongation at Break | ISO 527-2 | 20 – >150 % |

| Flexural Strength | — | ~170 MPa |

Thermal Properties

3D-PEEK-1000 Faliment

| Property | Typical Value |

|---|---|

| Heat Deflection Temp. (1.8 MPa) | ~160 °C |

| Continuous Service Temp. | -30 °C to +250 °C |

| Short-Term Peak Temp. | Up to 310 °C |

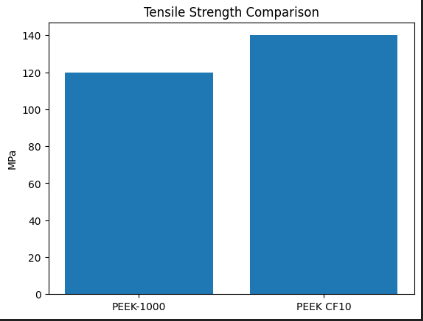

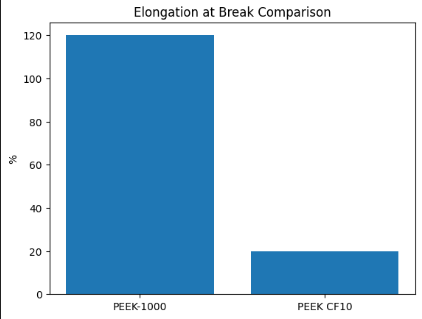

Performance Comparison Charts

The bar charts above highlight key performance differences:

-

Tensile Strength:

PEEK-1000 offers excellent strength while maintaining superior toughness. -

Elongation at Break:

PEEK-1000 dramatically outperforms carbon-fiber-reinforced PEEK grades, making it ideal for impact-resistant and fatigue-critical applications.

These characteristics make PEEK-1000 the preferred grade where ductility and toughness are more important than maximum stiffness.

Recommended 3D Printing Parameters

3D-PEEK-1000 Faliment

| Parameter | Recommended Range | Notes |

|---|---|---|

| Nozzle Temperature | 390 – 440 °C | Hardened steel or ruby nozzle required |

| Bed Temperature | 130 – 160 °C | PEI, Garolite or high-temp surface |

| Chamber Temperature | >70 °C (Ideal >90 °C) | Actively heated chamber essential |

| Print Speed | 20 – 40 mm/s | Slower speeds improve layer adhesion |

| Cooling Fan | OFF | Prevents thermal shock |

| Filament Drying | Mandatory | 120–150 °C for 6–8 hours |

Important: PEEK-1000 requires a high-temperature industrial 3D printer. Desktop printers are not suitable.

Why Choose PEEK-1000 in Westmead NSW 2145, Australia

-

Ideal for medical research, hospitals, and universities in Westmead

-

Perfect for industrial tooling and functional prototypes

-

Excellent choice for Australian engineering, mining, and manufacturing sectors

-

Local availability and technical support in NSW 2145

-

Suitable for sterilisation-ready and chemically aggressive environments

SEO Keywords Included

-

PEEK-1000 filament Westmead NSW 2145

-

Pure PEEK 3D printing filament Australia

-

High-toughness PEEK filament NSW

-

Medical-grade PEEK filament Westmead

-

Industrial PEEK filament New South Wales

-

High-temperature PEEK 3D printing material Australia

Summary

PEEK-1000 Filament is the ultimate choice for applications requiring maximum toughness, ductility, chemical resistance, and thermal stability. As an unfilled PEEK grade, it delivers superior impact resistance and fatigue performance, making it ideal for medical, aerospace, chemical, and industrial engineering applications.

For organisations and innovators in Westmead, New South Wales 2145, PEEK-1000 provides a reliable, high-performance solution capable of replacing metal and outperforming conventional engineering plastics in extreme environments.

FAQ – PEEK-1000 Filament (Unfilled High-Performance PEEK)

Westmead NSW 2145, Australia

1. What is PEEK-1000 filament?

PEEK-1000 is a 100% pure, unfilled Polyetheretherketone (PEEK) filament designed for extreme engineering applications. It offers outstanding toughness, chemical resistance, thermal stability, and mechanical performance, making it ideal for industrial, aerospace, medical (non-implant), and research applications in Westmead NSW 2145 and across Australia.

2. How does PEEK-1000 differ from reinforced PEEK filaments like PEEK-CF10?

PEEK-1000 is unfilled, while PEEK-CF10 contains carbon fibre.

Key differences include:

-

Higher ductility and impact resistance (PEEK-1000)

-

Much higher elongation at break

-

Better fatigue performance

-

Slightly lower stiffness than carbon-fibre-reinforced grades

PEEK-1000 is preferred where toughness and flexibility are more important than maximum rigidity.

3. What are the main advantages of PEEK-1000?

PEEK-1000 provides:

-

Exceptional impact resistance

-

Excellent chemical and solvent resistance

-

High continuous operating temperature (~250°C)

-

Low moisture absorption

-

Inherent flame retardancy (UL94 V-0)

-

Excellent dimensional stability

-

High purity suitable for medical and laboratory use

4. What industries commonly use PEEK-1000 filament?

PEEK-1000 is widely used in:

-

Medical & healthcare (non-implantable tools, housings, guides)

-

Aerospace & defence

-

Chemical processing

-

Electrical & semiconductor manufacturing

-

Automotive engineering

-

Industrial tooling & fixtures

-

University & R&D laboratories in Westmead NSW

5. What are typical applications for PEEK-1000?

Common applications include:

-

High-temperature jigs & fixtures

-

Chemical-resistant housings and enclosures

-

Sterilisable medical device prototypes

-

Aerospace interior and structural components

-

Electrical insulation parts

-

Wear components and mechanical guides

-

Lightweight metal-replacement parts

6. Is PEEK-1000 suitable for medical applications?

Yes. PEEK-1000 is suitable for:

-

Medical device prototyping

-

Sterilisable components (steam, chemical, gamma)

-

Laboratory and diagnostic equipment

⚠ It is not intended for permanent implants unless specifically certified.

7. What temperature resistance does PEEK-1000 offer?

PEEK-1000 supports:

-

Continuous service temperature: up to ~250°C

-

Short-term exposure: up to ~310°C

-

Excellent mechanical stability under thermal stress

This makes it ideal for high-temperature industrial environments.

8. How chemically resistant is PEEK-1000?

PEEK-1000 is highly resistant to:

-

Fuels and oils

-

Acids and alkalis

-

Solvents and hydrocarbons

-

Saltwater and corrosive chemicals

This makes it suitable for chemical processing and mining environments, including those found in Australian industry.

9. What type of 3D printer is required for PEEK-1000?

PEEK-1000 requires an industrial-grade high-temperature 3D printer with:

-

Nozzle temperature: 390–440°C

-

Heated bed: 130–160°C

-

Heated chamber: ≥70°C (ideally ≥90°C)

-

Hardened steel or ruby nozzle

Standard desktop printers are not compatible.

10. Is filament drying required before printing?

Yes. Drying is mandatory:

-

Dry at 120–150°C for 6–8 hours

-

Store in a dry box or vacuum-sealed packaging

Proper drying is critical for layer adhesion and surface quality, especially in humid conditions.

11. Is PEEK-1000 abrasive to printer components?

No. Since PEEK-1000 is unfilled, it is less abrasive than carbon-fibre-reinforced filaments.

However, high temperatures still require high-quality nozzles.

12. Is PEEK-1000 flame retardant?

Yes. PEEK-1000 is inherently flame retardant and typically meets UL94 V-0 without additives, making it suitable for electrical and safety-critical applications.

13. How does PEEK-1000 compare to PPS or PEI (ULTEM)?

| Material | Toughness | Heat Resistance | Chemical Resistance | Print Difficulty |

|---|---|---|---|---|

| PEEK-1000 | ★★★★★ | ★★★★★ | ★★★★★ | Very High |

| PPS | ★★★★☆ | ★★★★☆ | ★★★★★ | High |

| PEI (ULTEM) | ★★★★☆ | ★★★★☆ | ★★★★☆ | High |

PEEK-1000 offers the best overall balance of toughness, purity, and thermal performance.

14. How should PEEK-1000 filament be stored?

Store PEEK-1000:

-

In vacuum-sealed or airtight containers

-

With desiccant

-

Away from humidity and direct heat

Proper storage ensures consistent printing performance in Westmead NSW 2145.

15. Where can I buy PEEK-1000 filament in Westmead NSW 2145, Australia?

PEEK-1000 filament is available from specialised Australian industrial filament suppliers that deliver directly to Westmead NSW 2145. Local supply ensures fast delivery, technical support, and compliance with Australian engineering standards.