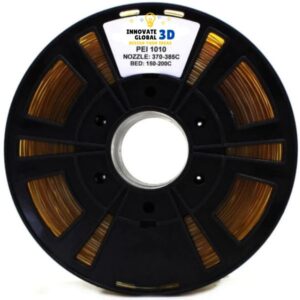

PEI 1010 3D Filament, Made using ULTEM™ PEI 1010

We manufacture this ultra-performance 3D printing filament using ULTEM™ 1010 PEI (polyether imide) resin. PEI is an amorphous, high-performance polymer that combines excellent thermal properties, exceptional dimensional stability, inherent flame retardancy, and good chemical resistance. Filaments made using ULTEM™ 1010 resin offers the ability to create parts with excellent properties at elevated temperatures due to a high glass transition temperature (Tg) of 217°C.

Product attributes include:

• High thermal properties: (Tg) of 217°C

• Inherent flame resistance

• Long-term hydrolytic stability

• Excellent dimensional stability (low creep sensitivity and low, uniform coefficient of thermal expansion) and highly reproducible part-to-part dimensions

• Exceptional strength and modulus, even at elevated temperatures

• Good resistance to a broad range of chemicals, such as automotive fluids, fully halogenated hydrocarbons, alcohols, and aqueous solutions

• Stable dielectric constant and dissipation factor over a wide range of temperatures and frequencies

Automotive / Transportation Applications: ULTEM™ resins provide automotive manufacturers with a high-performance, chemically resistant, thermally-stable, cost-effective alternative to metal that is strong enough to replace steel in some applications and light enough to replace aluminum in others. For applications like transmission components, throttle bodies, ignition components, sensors, and thermostat housings,

Electrical / Electronics Applications: ULTEM™ resin may be an excellent material choice for today’s demanding electrical applications, including connectors, MCB components like housings, shafts and levers, hard disk drive internals, FOUPs, BiTS, PCBs, MCCB internals, Plenum devices, LCD projector internals, fuel cell components, and many other applications.

Filament Specifications:

• Diameter: 1.75mm (+/- 0.05mm)

• Colors: Natural and Black

Recommended Print Conditions:

• Extruder Temp: 370 – 390°C

• Bed Temp: 160-200°C

• Bed Prep: Rough Borosilicate Glass with PVP gluestick, or high temp carbon fiber sheet plus PVP glue stick, we also recommend the Vision Miner Nano Polymer

• Print Speed: Print speeds of 20-30mm/s (starting point), faster as results dictate

• Enclosure Temp: 90-200°C (Bigger the part higher chamber temps are required)

• Drying Instructions: Please dry at @110-120°C for 12-24 hours, for the first dry its recommended to dry for at least 24 hours before using, the drying time can be lowered using a vacuum oven, and also storing the filament in a degassing chamber when not in use.

ULTEM™ is a registered trademark of Sabic Innovative Plastics.

3DAMSS manufactures this filament using ULTEM™ 1010 PEI resin. See More

Here is a table format for the description provided:

| Category | Details |

| Product Name | Neat Filament – PEI 1010 |

| Material | ULTEM™1010 Resin (Amorphous, High-Performance Polymer) |

| Key Features | · High thermal properties: Tg of 217°C · Inherent flame resistance · Long-term hydrolytic stability · Excellent dimensional stability (low creep sensitivity and uniform coefficient of thermal expansion) · Exceptional strength and modulus, even at elevated temperatures |

| Filament Specifications | – Diameter: 1.75mm +/- 0.05mm – Colors: Natural and Black |

| Recommended Print Settings | – Nozzle Temperature: 370–390°C – Bed Temperature: 160–200°C- Bed Preparation: Rough borosilicate glass with PVP glue stick OR high-temp carbonfiber sheet plus PVP glue stick – Adhesive Recommendation: Vision Miner Nano Polymer Adhesive |

| Technical Stability | Workable for up to 12 months from delivery |

| Contact Information | · Phone: +61447809195 · Email: innovate3dglobal@gmail.com · Website: https://innovate3dglobal.com/ |

| Company Information | Innovate3Dglobal Pty Ltd. Ashley Lane, 19/1A, Westmead, New South Wales 2145, Australia |

Advantages of PEI 1010

- High strength-to-weight ratio for demanding industrial applications.

- Flame-retardant properties meet safety standards.

- Dimensional stability ensures precision across printed parts.

- Long-term resistance to water and chemicals for extended durability.

Professional-Grade Performance

PEI.1010 filament from Innovate3Dglobal Pty Ltd ensures that manufacturers and engineers can rely on consistent, high-performance results. Its excellent properties at elevated temperatures and flame-resistant characteristics make it indispensable in high-stress environments, particularly where precision and durability are essential.

The compatibility with advanced 3D printing techniques and adhesives like Vision Miner Nano Polymer ensures smooth adhesion to build plates, minimizing warping and improving reliability. Innovate3Dglobal Pty Ltd’s strict quality standards mean every filament roll meets rigorous performance criteria.

Usage Guidelines

- Always store the filament in a dry environment with controlled humidity to preserve its quality for the 12-month usability period.

- Clean nozzle and print bed before initiating prints for optimal results.

- Use the recommended bed preparations to achieve superior adhesion and reduce the risk of failed prints.

TECHNICAL DATASHEET: PEI.1010 3D PRINTING FILAMENT (MADE USING ULTEM 1010)

| TEST ITEM | TEST METHODS | UNITS | SPECIFICATIONS | RESULTS |

| TENSILE STRENGTH | ISO 527 | MPa | 55 | |

| TENSILE ELONGATION | ISO 527 | % | 3 | |

| TENSILE MODULUS | ISO 527 | MPa | 2490 | |

| FLEXURAL MODULUS | ISO 178 | MPa | 2450 | |

| FLEXURAL STRENGTH | ISO 178 | MPa | 105 | |

| SPECIFIC GRAVITY | ISO 1183 | G/CC | 1.27 | |

| GLASS TRANSITION TEMPERATURE | ISO 11357 | C | 217C |

THE ABOVE DATA IS DERIVED FROM THE RAW MATERIAL SUPPLIER, AND WAS ARRIVED WITH INJECTION MOLDING SPECIMENS, THE VALUES MAY VARY WITH DIFFERENT 3D PRINTERS AND DIFFERENT PROCESSING METHODS

PROCESS PARAMETERS :-

NOZZLE :- 360-380C, BED :- 160-200C, CHAMBER:-120-200C

Disclaimer: The technical data contained on this data sheet is furnished without charge or obligation and accepted at the recipient’s sole risk. This data should not be used to establish specifications limits or used alone as the basis of design. The data provided is not intended to substitute any testing that may be required to determine fitness for any specific use.

ULTEM IS A REGISTERED TRADEMARK OF SABIC IP

Neat Filament Overview

Neat Filaments, offered by Innovate3Dglobal Pty Ltd, represent the pinnacle of high-performance 3D printing materials. These filaments are meticulously crafted for applications that demand superior strength, thermal stability, and exceptional dimensional accuracy. Designed to meet the stringent requirements of various industries, Neat Filaments are perfect for manufacturing, engineering, and prototyping needs.

Key Features

- High Thermal Properties: Neat Filaments exhibit excellent heat resistance, making them suitable for demanding applications in automotive, aerospace, and industrial sectors.

- Dimensional Stability: They ensure precise, reproducible part dimensions, thanks to a low coefficient of thermal expansion and resistance to deformation.

- Flame Retardancy: Inherent flame-resistant properties make these filaments ideal for environments where safety is paramount.

- Chemical Resistance: Robust against various chemicals, these filaments maintain their integrity in harsh conditions.

- Exceptional Strength: Neat Filaments deliver remarkable strength and rigidity, even at elevated temperatures.

Applications

Neat Filaments cater to a wide range of industries, including:

- Automotive: For parts requiring durability and heat resistance.

- Electronics: Suitable for components exposed to high temperatures.

- Aerospace: Used in lightweight yet strong parts.

- Industrial Equipment: For tools and functional prototypes that endure stress and wear.

Recommended Printing Settings

- Nozzle Temperature: Between 370°C – 390°C.

- Bed Temperature: 160°C – 200°C.

- Bed Preparation: Compatible with rough borosilicate glass, high-temp carbon fiber sheets, or Vision Miner Nano Polymer adhesive for optimal results.

Reviews

There are no reviews yet.