PEEK-CF10

AUD$1,234.00

- Weight: 1KG

- 10% Carbon Fiber Reinforced PEEK 3D Filament.

- PEEK-CF10 is one of the premier polymers in FFF/FDM 3D Printing.

- Made using 10% chopped carbon fiber for exceptional stiffness, strength, and dimensional stability.

- PEEK is one of the highest-performance thermoplastics ever invented.

10% Carbon Fiber Reinforced PEEK 3D Filament

PEEK-CF10 is one of the premier polymers in FFF/FDM 3D Printing. Made using 10% chopped carbon fiber for exceptional stiffness, strength, and dimensional stability.

PEEK is one of the highest-performance thermoplastics ever invented. It is used in some of the most demanding applications such as seals, gears, bushings, bearings, and pump & compressor components. Industries such as Auto, Aerospace, Defense, Semiconductor, and Oil/Gas depend on PEEK for applications where failure is not an option.

PEEK Properties Include:

• Superior Mechanical Properties, especially at elevated temperatures

• Excellent Chemical Resistance

• Low Coefficient of Linear Thermal Expansion (CTE)

• Near Zero Moisture Absorption

• Low smoke and toxic gas emissions

PEEK has excellent resistance to hydrolysis in boiling water and superheated steam (sterilization/autoclave) at temperatures in excess of 250°C (482°F).

PEEK-CF10 Thermal Properties:

• Heat Deflection Temperature (HDT) 280°C (when crystalized)

• Glass Transition Temperature (Tg) 143°C

• Melt Temperature (Tm) 343°C

Printing with PEEK-CF10

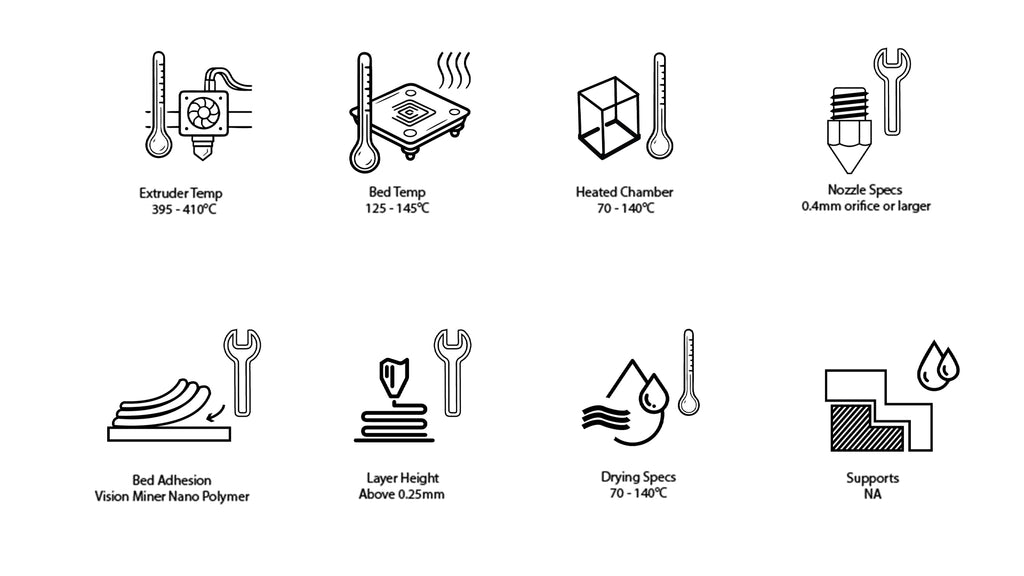

• Extruder Temps: 395 – 410°C

• Bed Temps: 125 – 140°C

• Bed Prep: Rough Borosilicate Glass with PVP gluestick, or High temp carbon fiber sheet plus PVP glue stick, we also recommend the Vision Miner Nano Polymer

• Nozzle: We strongly recommend a 0.4mm orifice or larger using one of our Carbide nozzles

• Layer Height: Ideal layer height is 60% of nozzle diameter. We do not recommend printing layers below 0.25mm with carbon fiber grades. Lower than 0.25mm may create too much back pressure in the hot end and result in poor feeding, jams, drive gear clicking, and eating a notch into the filament.

• Please note – CF-PEEK has a tendency to stick to metal (PEEK loves metal). Please make sure to purge out your extruder before it cools down or you run the risk of permanent clogs.

• Drying Instructions: Please dry @110-120°C for 12-24 hours, for the first dry its recommended to dry for at least 24 hours before using, the drying time can be lowered using a vacuum oven and also storing the filament in a degassing chamber when not in use.

• Enclosure temp (if your printer is equipped): 70 – 140°C [hotter is better, up to 140°C]

| Weight | 1 kg |

|---|---|

| Weight | 1 KG |

Reviews

There are no reviews yet.