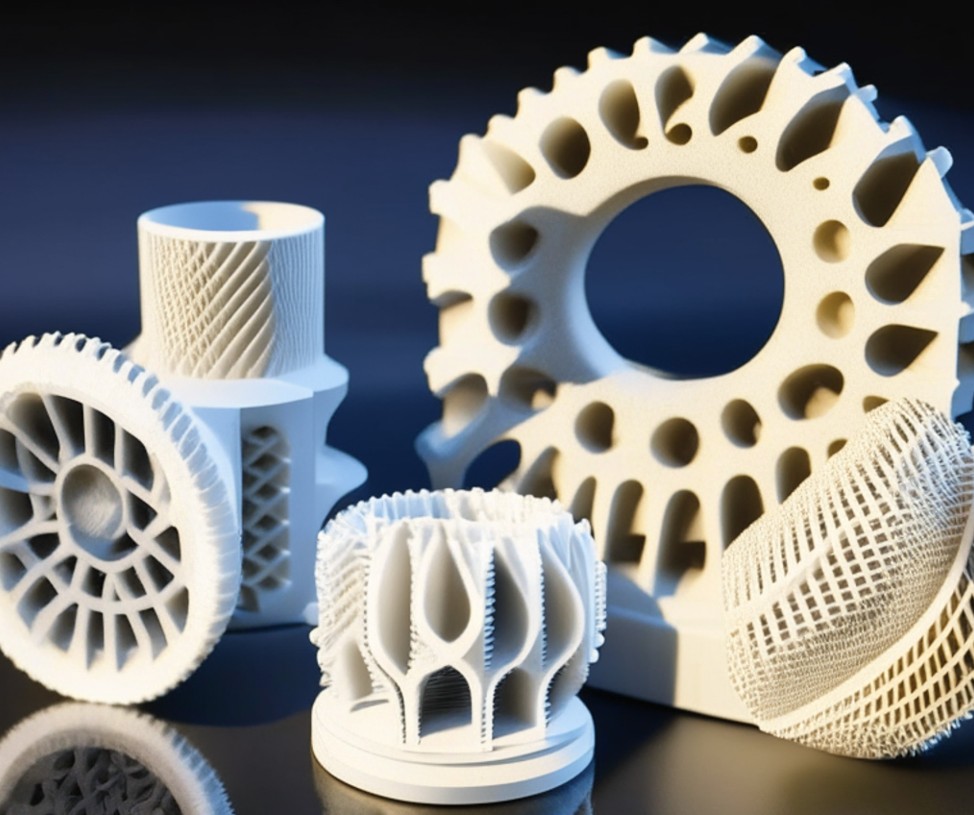

In the realm of 3D printing, one material has gained significant attention for its exceptional properties and versatility: The PEEK filament.

Polyether Ether Ketone (PEEK) filament is revolutionizing various industries by offering a range of unique advantages over traditional materials.

In this blog post, we’ll delve into the applications, limitations, and advantages of PEEK filament, showcasing its incredible potential. And if you’re looking to harness the power of PEEK, don’t forget to check out our website, Innovate3Dglobal, for high-quality PEEK filament options.

Application of PEEK Filament

PEEK’s high strength-to-weight ratio and excellent thermal stability make it a perfect choice for aerospace applications.

It is used in manufacturing lightweight yet robust components such as ducting systems, brackets, and connectors, ensuring optimal performance and durability in extreme conditions.

PEEK’s biocompatibility, chemical resistance, and radiolucency make it an ideal material for medical devices. It is widely used in orthopedic implants, surgical instruments, dental applications, and prosthetics, providing strength, biocompatibility, and ease of sterilization.

PEEK’s ability to withstand high temperatures and mechanical stress makes it invaluable in the automotive industry.

It finds applications in engine components, electrical connectors, and under-the-hood parts, offering superior performance and longevity.

PEEK’s excellent chemical resistance and mechanical properties make it suitable for various industrial applications. It is commonly utilized in seals, gaskets, bearings, and pump components, where its stability and durability are essential.

Limitations and Advantages of PEEK Filament

PEEK filament is relatively more expensive compared to other thermoplastics, making it less accessible for some applications.

However, the benefits it provides often outweigh the initial investment. PEEK filament requires specific printing conditions due to its high melting point and slow cooling rate.

Specialized equipment, such as high-temperature extruders and heated print beds, are necessary for successful prints. Additionally, users may need to optimize print settings and experiment to achieve desired results.

PEEK can withstand continuous use at temperatures up to 250°C (482°F) and short-term exposure up to 300°C (572°F). This makes it suitable for applications requiring thermal stability.

PEEK is highly resistant to various chemicals, including acids, bases, solvents, and fuels. It maintains its structural integrity and mechanical properties even when exposed to harsh chemical environments.

PEEK filament offers exceptional mechanical properties, including high tensile and flexural strength and excellent fatigue resistance. This makes it an ideal choice for applications where structural integrity is crucial.

PEEK is an excellent electrical insulator, providing high dielectric strength and low moisture absorption. It is widely used in electrical and electronic components where insulation and reliability are vital.

Ready to explore the incredible potential of PEEK filament?

Visit our website, Innovate3Dglobal, to discover a wide range of high-quality PEEK filament options that meet your specific needs.

Whether in aerospace, medical, automotive, or any other industry, our PEEK filament will empower you to create durable, high-performance parts.

Don’t miss out on the opportunity to revolutionize your manufacturing processes with PEEK filament—take the first step towards innovation today!

And please do share your challenges faced in your manufacturing processes or Contact us to discuss.