Carbon Fiber Filament has emerged as a game-changer in the world of 3D printing, offering unparalleled strength and lightweight characteristics.

In this article, we will explore the wide-ranging applications, limitations, and advantages of Carbon Fiber Filament.

If you’re eager to harness the power of this cutting-edge material, look no further than Innovate3Dglobal.

Visit our website to explore our high-quality Carbon Fiber Filament options and elevate your 3D printing capabilities.

Applications of Carbon Fiber Filament

Carbon Fiber Filament finds extensive use in the aerospace and aviation industries, where the strength-to-weight ratio is critical.

It is utilized to create lightweight, durable components such as drone frames, aircraft interiors, and structural parts, enhancing overall performance and fuel efficiency.

Carbon Fiber Filament revolutionizes the automotive industry by enabling the production of lightweight, high-strength parts.

From chassis components to custom body panels, this filament delivers superior strength while reducing weight, and enhancing speed, and fuel efficiency.

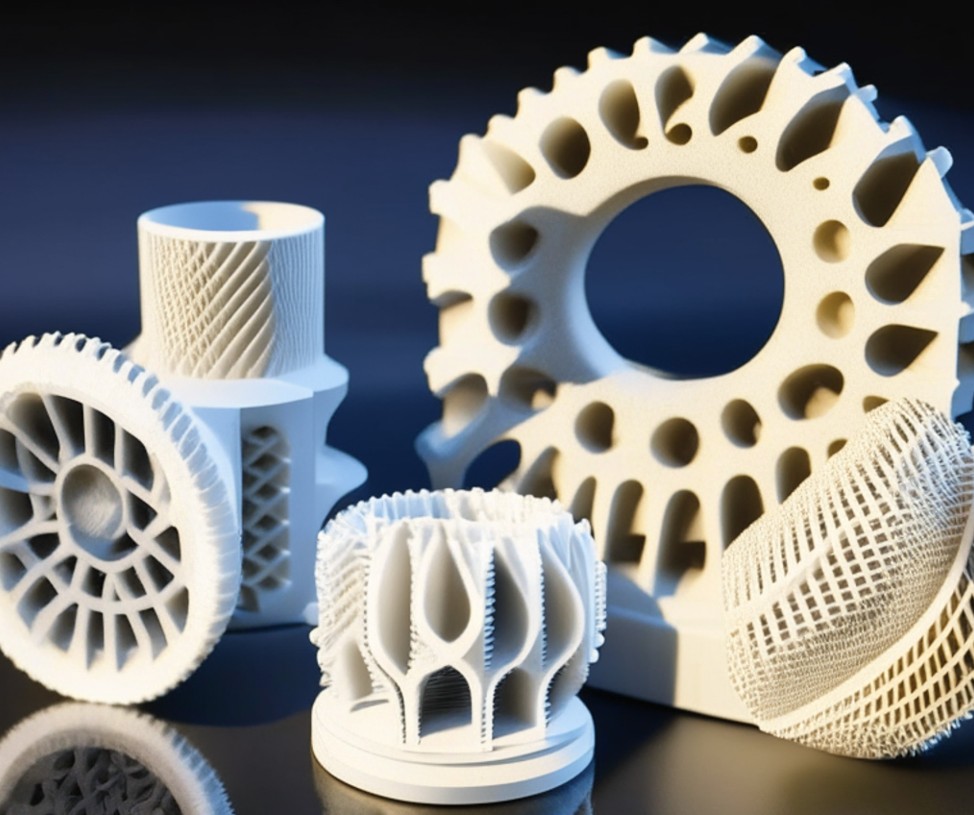

Carbon Fiber Filament is increasingly employed in industrial manufacturing for its excellent mechanical properties.

It is used to fabricate robust and wear-resistant parts, jigs, fixtures, and tools, optimizing efficiency and durability in production processes.

The exceptional strength and rigidity of Carbon Fiber Filament make it ideal for creating robotic components and automated systems.

It provides stability, precision, and durability to critical parts such as robot arms, grippers, and end-effectors, enabling smoother and more efficient operations.

Scope of Carbon Fiber Filament

CF Filament is relatively more expensive compared to standard filaments due to the complexity of its manufacturing process.

However, the cost is often justified by the enhanced performance and durability it offers.

The presence of carbon fibers in the filament can make it abrasive, causing increased wear on printer nozzles.

Specialized nozzles made of hardened materials are recommended for optimal performance.

Additionally, the high heat conductivity of carbon fibers may require modified printing settings to ensure successful prints.

Benefits of Carbon Fiber Filament

CF Filament provides exceptional strength while being incredibly lightweight.

It outperforms traditional materials like plastics and metals in terms of strength, making it an ideal choice for applications where weight reduction and structural integrity are crucial.

Parts printed with Carbon Fiber Filament exhibit high rigidity and dimensional stability.

They maintain their shape under stress and exhibit minimal deformation, ensuring accuracy and reliability in various applications.

Carbon Fiber Filament possesses excellent resistance to heat and chemicals, allowing it to withstand harsh environments.

It retains its structural integrity and mechanical properties even at elevated temperatures, making it suitable for demanding applications.

The inherent toughness of Carbon Fiber Filament makes printed parts highly durable.

They can withstand impact and repetitive stress, reducing the risk of failure and increasing overall longevity.

Elevate your 3D printing capabilities and unlock new possibilities with CF Filament from Innovate3Dglobal.

Visit our website to explore our extensive range of high-quality CF Filament options, tailored to meet your specific requirements.

Revolutionize your projects in aerospace, automotive, industrial manufacturing, robotics, and more.

Don’t miss out on the opportunity to transform your ideas into reality with the strength and versatility of Carbon Fiber Filament. Take the first step towards innovation today!

Полезные советы по безопасной покупке диплома о высшем образовании

Полезная информация как купить диплом о высшем образовании без рисков